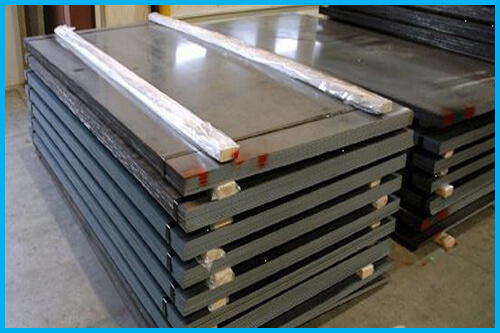

In industries where abrasion, impact, and friction are constant challenges, material failure is not an option. From mining pits to cement plants, equipment faces relentless wear every single day. This is where wear plates step in as silent protectors. Designed to extend service life and reduce maintenance downtime, wear plates are essential components in demanding industrial environments. Their strength, toughness, and resistance to surface damage make them a dependable solution for businesses that value durability and operational efficiency.

Body

Wear plates are specially engineered steel plates manufactured to withstand harsh working conditions. Unlike standard structural steel, these plates are produced with enhanced hardness and resistance to abrasion. This ensures they can endure continuous rubbing, sliding, or impact without losing their structural integrity.

Industries such as mining, construction, power generation, recycling, and material handling rely heavily on wear plates. Equipment like hoppers, crushers, dump truck bodies, chutes, buckets, and conveyors frequently operate under abrasive conditions. Without proper protection, these components would wear out quickly, leading to costly repairs and downtime.

The manufacturing process of wear plates often involves controlled rolling, precise heat treatment, and strict quality testing. These processes ensure uniform hardness throughout the plate and maintain the balance between strength and workability. While high hardness improves wear resistance, adequate toughness prevents cracking under impact loads.

Selecting the right wear plate depends on application requirements. Factors such as material being handled, impact intensity, temperature exposure, and fabrication needs all influence the final choice. When properly selected and installed, wear plates significantly reduce operational costs over time.

Key Features

• Excellent abrasion resistance

• High hardness levels for extended service life

• Strong impact resistance

• Good weldability and fabrication capability

• Consistent mechanical properties

• Reduced maintenance frequency

• Cost-effective long-term performance

Types

Wear plates are available in various grades and compositions, each designed for specific performance requirements:

-

Abrasion-Resistant Steel Plates (AR Plates) – Known for high surface hardness and resistance to sliding wear.

-

Quenched and Tempered Wear Plates – Offer a balance between hardness and toughness.

-

Chromium Carbide Overlay Plates – Feature a hard overlay layer for extreme abrasion environments.

-

Heat-Treated Alloy Wear Plates – Designed for applications requiring enhanced strength and durability.

-

High-Impact Wear Plates – Engineered to handle heavy shock loads along with abrasion.

Each type is tailored to meet the needs of different industries and working conditions.

Applications

Wear plates play a vital role in numerous industrial sectors:

• Mining equipment such as excavator buckets and dump trucks

• Cement industry components like liners and chutes

• Construction machinery including loaders and crushers

• Steel plants for material transfer systems

• Power plants handling coal and ash

• Recycling units processing scrap and waste materials

Their ability to withstand harsh materials like gravel, coal, ore, sand, and slag makes them indispensable in heavy-duty operations.

Conclusion

Wear plates are more than just protective steel sheets; they are a smart investment in reliability and performance. By offering superior resistance to abrasion and impact, they enhance equipment life, reduce downtime, and improve overall productivity. Choosing the right wear plate ensures smoother operations and long-term cost savings. For industries operating in challenging environments, wear plates remain an essential solution that delivers strength where it matters most.